Company at a Glance

NATIONAL HEAT TREATMENT CENTRE LTD

The National Heat Treatment Centre (NHTC) began life in University College Dublin in 1993 as a funded research centre led by David Collins, a lecturer in Metallurgy in the Mechanical Engineering Department.

To help finance the research operation, it offered contract heat treating services and metallurgical analysis to the engineering industry, predominantly the emerging tool-making sector.

Striving to provide an excellent service

Services Overview

In our continuing endeavour to offer core services to the tool making industry, we are pleased to announce the commissioning of our Metallurgical Laboratory which now enables us to provide sophisticated mechanical testing, and chemical analysis of metals as an additional service to our customers. Browse our scope and range of the services offered together with the scale of charges for each test.

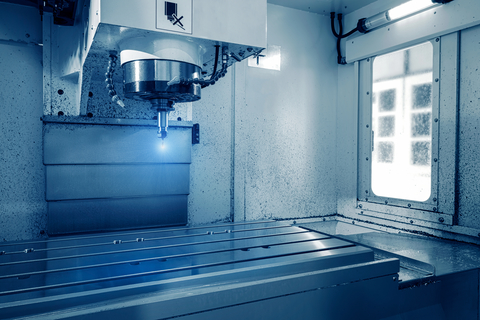

HARDENING AND TEMPERING OF TOOL AND DIE STEELS

Hardening involves controlled heating to a critical temperature dictated by the type of steel (in the range 760- 1300°C) followed by controlled cooling. Dependent on the type of material, appropriate cooling rates vary from very fast (water quench) to very slow (air cool). Tempering involves reheating the hardened tool/die to a temperature between 150-675°C, depending on the steel type. A process which controls final properties whilst relieving stresses after hardening, tempering can be com- plex; some steels must be subjected to multiple tempering operations.

NITRIDING AND NITROCARBURISING

Gaseous Nitriding is conducted in gas (490-560°C) for treatment times ranging up to 90 hours and involves the diffusion of nitrogen into the surface to produce a controlled depth of hard alloy-nitrides. Unlike the high-temperature case-hardening treatments (carburizing / carbonitriding), hardening is achieved without the need for quenching. Nitrocarburising is generally of shorter duration (30 minutes - 5 hours), involves enrichment of the surface with both nitrogen and carbon to impart a thin iron-carbonitride “compound layer” supported by a nitrogen-bearing “diffusion zone” and conducted at temperatures of 560-580°C.

CARBURISING AND CARBONITRIDING

Carburising and carbonitriding are “thermochemical” treatments, usually conducted at temperatures in the range 800-940°C, in the first stage of “case-hardening”. These processes change the chemical composition of the surface of a low-carbon steel component so that subsequent fast cooling, by “quenching”, produces a hard “case” combined with a softer/tougher “core”. Quenching is normally followed by a low-temperature tempering / stress relieving treatment.

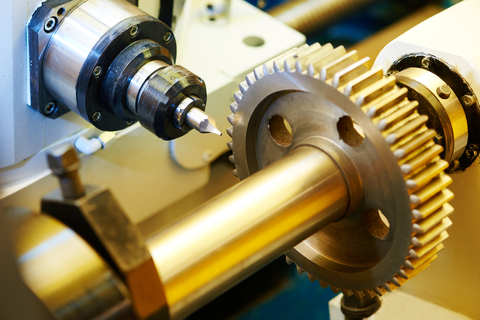

INDUCTION HARDENING

Induction hardening is a method for hardening the surfaces of components, usually in selected areas, by the short-time application of high-intensity heating followed by quenching. The heating and hardening effects are localised and the depth of hardening is controllable. Unlike thermochemical case-hardening treatments (carburising / carbonitriding) applied to low-carbon steels, induction hardening does not promote chemical enrichment of the surface with carbon, but rely on the presence of an adequate carbon content already in the material to achieve the hardness level required.

STRESS RELIEVING, NORMALISING AND ANNEALING

Stress relieving is applied to both ferrous and non-ferrous alloys and is intended to remove internal residual stresses generated by prior manufacturing processes such as machining, cold rolling and welding. Normalising is applied to some, but not all, engineering steels, normalising can soften, harden or stress relieve a material, depending on its initial state. The objective of the treatment is to counter the effects of prior processes, such as casting, forging or rolling, by refining the existing non-uniform structure into one which enhances machinability/formability or, in certain product forms, meets final mechanical property requirements. The primary purpose of an annealing treatment is to reduce the hardness of a material and facilitate the progress of subsequent manufacturing operations.

METALLURGICAL TESTING

Metallurgical Testing can involve Hardness Testing, Chemical Analysis, Mechanical Testing or Microstructure Analysis. This will give an accurate picture of the metals properties. Sometimes one of the tests are enough to verify that the part complies with the requirements or if a failure analysis is to be carried all of the above tests may have to be carried out on a sample.

Our advantages

HARDNESS TESTING

Most hardness tests consist of the penetration of the metal surface by a very hard indenter under load. The size of the resultant indent, with due regard for the applied load, is a measure of the hardness of the metal. Hardness can thus be defined as the resistance to indentation of a material. We offer a suite of Hardness tests

TENSILE TESTING

A prepared sample of material is pulled apart under an axial load, determining the yield strength, tensile strength, and elongation of the material.

CHARPY IMPACT TEST

A useful test to determine the degree of embrittlement (if any) of the test material

METALLOGRAPHY

Inspection of the microstructure of a metal sample

FAILURE ANALYSIS

Undertaking of a detailed investigation of failure including various inspections and analysis techniques.

CHEMICAL ANALYSIS

A non-mechanical test to determine the mechanical properties of engineering alloys and their response to heat treatment